Drone surveying has become a must-have for many land-surveying and construction firms. It helps gather precise site data, create 3D maps, and monitor progress without slowing down a job. But a new concern is making many professionals pause. Recent U.S. import changes and pending regulations could limit which drones are allowed into the country — and which ones can still receive software support.

For companies that depend on drone surveying every day, that uncertainty isn’t just a news headline. It could shape how smoothly projects move over the next year.

Federal regulators have begun tightening drone import and certification rules. The goal is to protect national security, but the process might also restrict certain drone brands that dominate the American market. If those reviews aren’t completed on time, new import approvals could be paused — and that means fewer replacement drones, fewer spare parts, and slower firmware updates.

For surveyors, this change hits close to home. Local firms rely on advanced drones for coastal mapping, construction staking, and infrastructure surveys. If popular brands face restrictions, even a small delay in supplies can ripple through schedules and budgets.

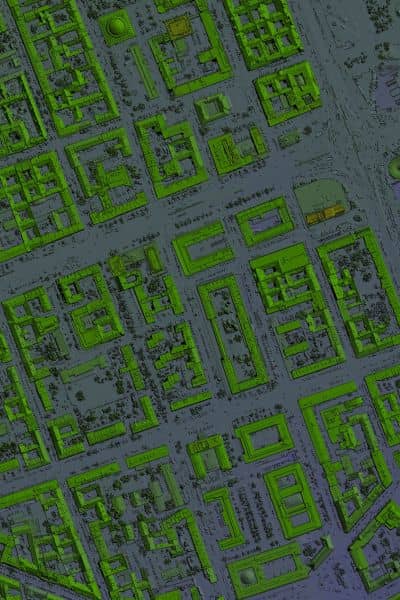

San Diego’s terrain is diverse — from flat coastal areas to hilly inland projects. Many teams rely on drones to capture accurate topography that would otherwise take days to measure. Construction companies, city planners, and environmental engineers all depend on these flights for permits, grading plans, and as-built documentation.

If the drone market suddenly narrows, replacing a damaged airframe or ordering new LiDAR sensors could take weeks instead of days. That delay might not sound huge, but for a firm balancing tight deadlines, it can cause chain reactions: postponed ground crews, rescheduled inspections, and unhappy clients.

Staying ahead of these disruptions starts with understanding what’s at stake — and building a plan around it.

Before new regulations take full effect, every company using drone surveying should perform a quick fleet audit. The process is simple but powerful:

This review helps you see exactly how ready your equipment is — and whether you can keep flying if supply chains tighten.

If you find that your drones rely heavily on one brand, build in some breathing room now. Stock extra batteries, propellers, and charging hubs. Keep at least one spare airframe on standby if your team flies multiple sites each week.

A good rule is to maintain enough spare parts to cover two months of active work. That gives you time to adapt if certain shipments slow down.

At the same time, download offline copies of any software or firmware you use for mapping and processing. That way, even if updates get delayed, your existing tools will keep working.

Your clients don’t follow drone-industry updates — they just want their maps and deliverables on time. Clear communication turns potential uncertainty into confidence.

A short message works well:

“We’re reviewing upcoming drone import and firmware changes and have already prepared our fleet to ensure smooth operations. Your scheduled aerial work remains on track.”

That one line does two things: it educates the client and reassures them you’re proactive. Transparency builds trust — and keeps your firm top-of-mind for future projects.

No one likes changing tools, but flexibility is key. Begin exploring alternative drone systems that meet your project needs. Compare performance, payload capacity, RTK accuracy, and software compatibility. Some American-made or European-certified drones now rival the quality of global brands.

If you test a new model, run a short field trial before adopting it. Gather data from a familiar job site and compare results to your existing system. The goal isn’t to replace your fleet overnight — it’s to know your options before you’re forced to switch.

Also, update your pilot training as you add new systems. A short internal workshop can prevent costly mistakes later.

Even if import rules change, your data remains the backbone of your business. Make sure all drone surveying files — point clouds, orthophotos, and elevation models — are stored in open, well-documented formats.

If you ever migrate to a different software or drone platform, you’ll be able to reprocess that data without losing accuracy. Consistent naming conventions and clear metadata (site name, date, coordinate system) also save time when revisiting past projects.

Policy updates can move quickly. Set up simple alerts through your professional associations or industry news sources. When new FAA or FCC announcements appear, read the summaries instead of the speculation.

Locally, firms can also coordinate with regional engineering and surveying groups. Sharing information about equipment shortages or import issues helps everyone plan better. Collaboration often beats competition when regulations shift.

Every change brings opportunity. As drone surveying evolves, we may see greater use of U.S.-made airframes, modular payloads, and automated docking systems that reduce field time. The coming year could push San Diego firms to modernize data workflows and strengthen compliance tracking — moves that pay off long after import issues settle.

Think of this moment as a stress test. By reviewing your fleet, confirming readiness, and diversifying suppliers, you’re future-proofing your entire surveying operation.

Uncertainty around U.S. drone imports doesn’t have to stop your projects. What matters is how you respond. Builders, developers, and land-surveying professionals have always adapted to new regulations — from flood-zone rules to airspace limits. This is no different.

Take a week to audit your fleet, refresh your backups, and talk with your team. Keep clients informed and stay flexible with your tools. If you do, you’ll glide through any transition while others scramble to catch up.

In short, review your drone surveying fleet now—so when the rules change, you’re already ready to fly.